My Monotype process combines the efficiency of many years of experience in fast-paced commercial presses with the care and attention that can be given to projects as a result of being a smaller operation.

Below is an overview of my process, from the making of a few design decisions, to the pressing and send-off

to the binders’.

Designing

Before the Monotype process can begin, certain elements

of the page design need to be chosen, such as the page size, typeface, leading, length of line (the measure), and more.

I am able to provide samples and a trained eye to help with these decisions.

Keyboarding

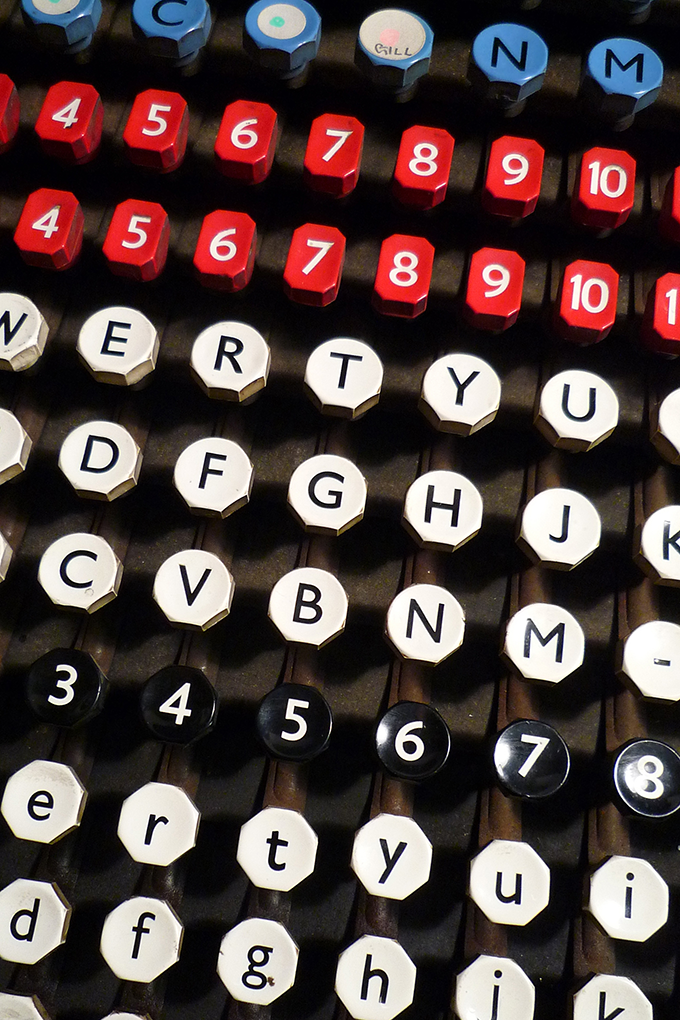

The Monotype pneumatic keyboard keybank.

The Monotype pneumatic keyboard keybar. Each typeface has its own set of keybars that match the matrices in the matrix-case layout.

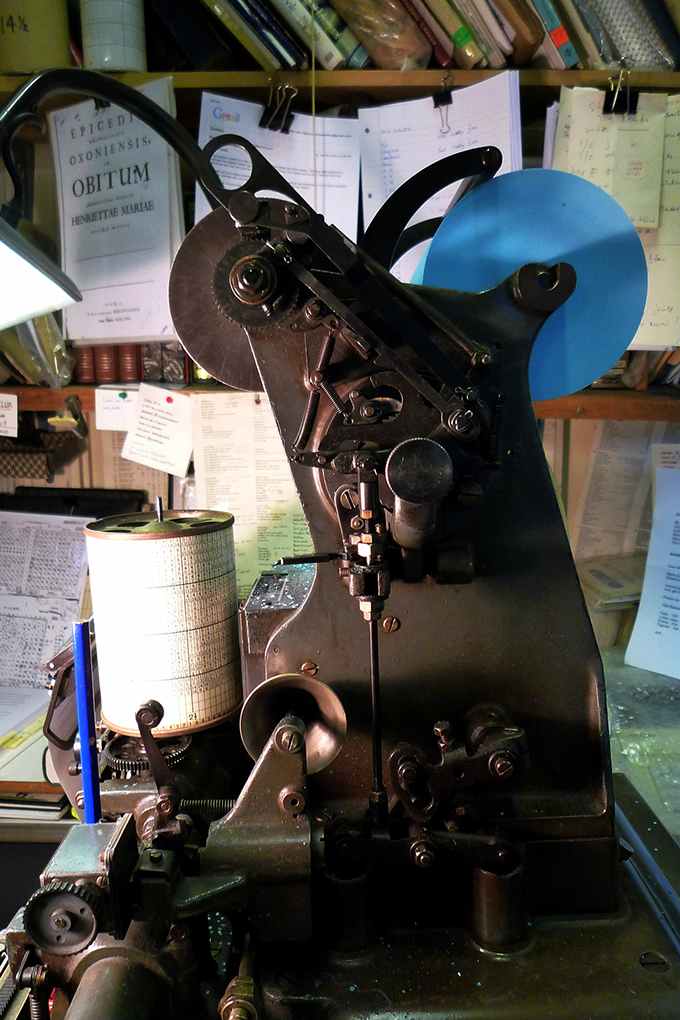

The Monotype pneumatic keyboard, producing the perforated paper tape (spool) for the Monotype caster. The perforations control the positioning of the matrix case over the mould when casting.

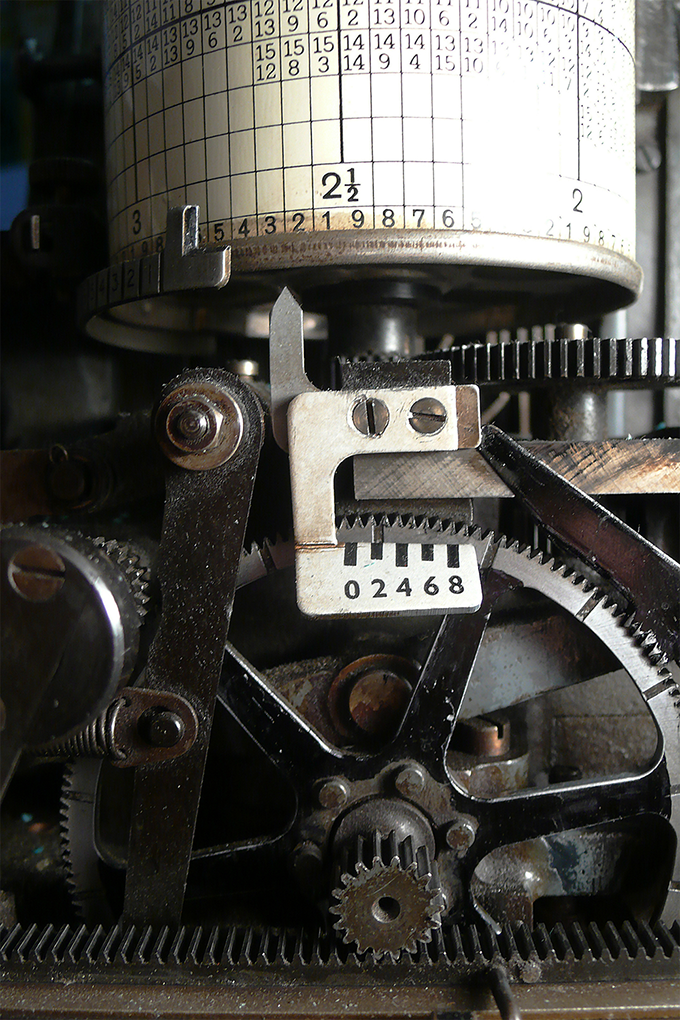

The 'justification drum', these figures operate the variable spaces to 'justify' the line to the measure on the caster.

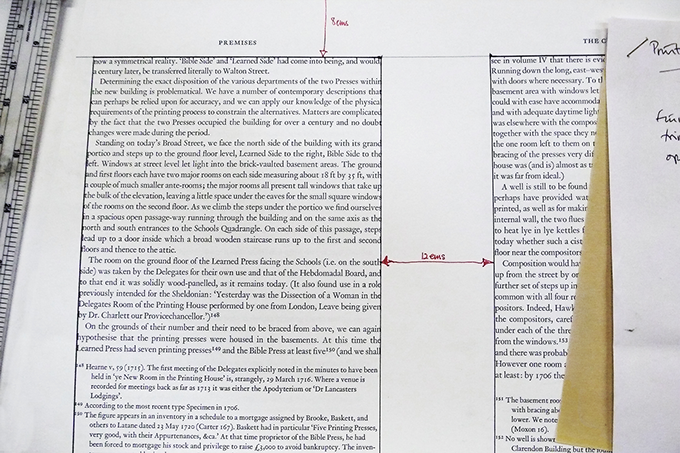

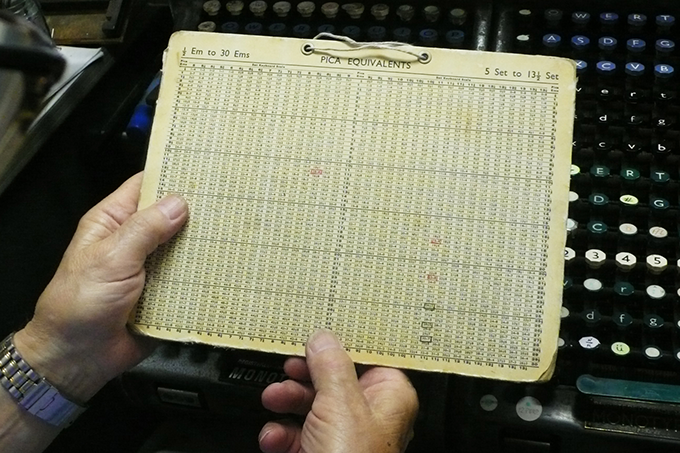

Calculation chart for the exact measure in various 'set' sizes.

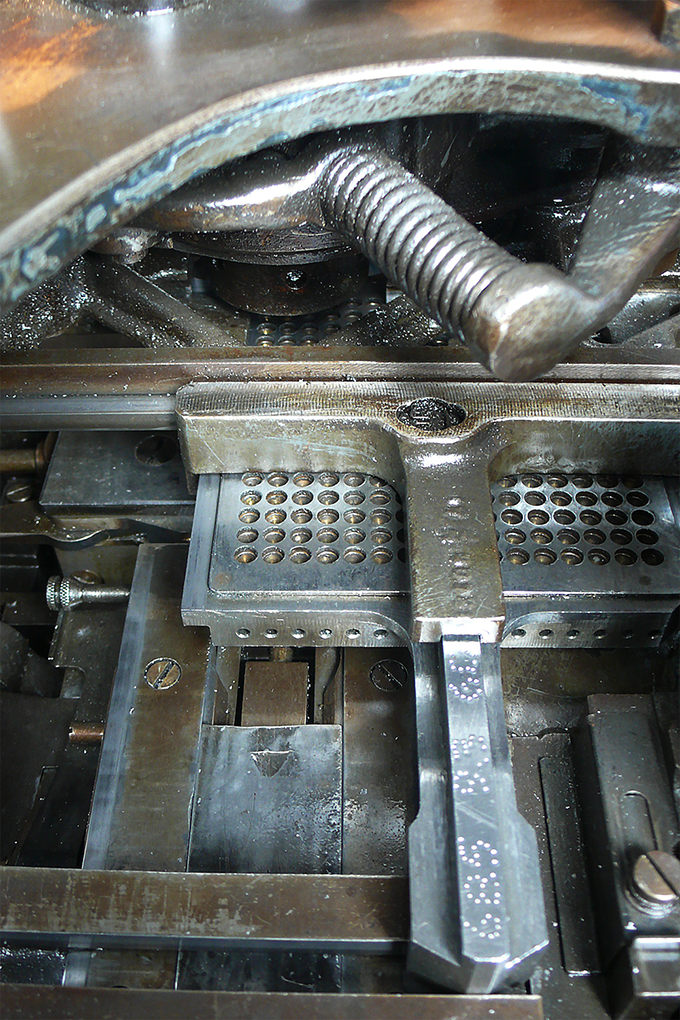

The Monotype composition caster. Molten type-metal flowing through the nozzle at 650 to 700 degrees Fahrenheit.

The perforated paper tape (spool) progressing on the Monotype composition caster, controlling the position of the matrix case over the mould. (The mould determines the body size of the type being cast and the matrix case determines the typeface size to be cast on that body.)

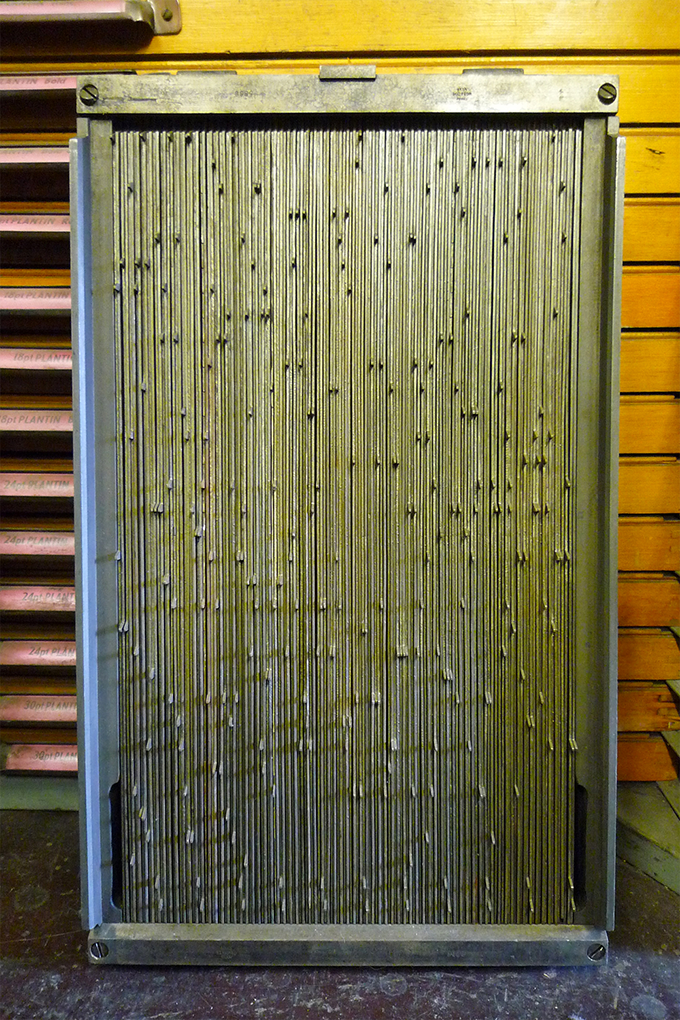

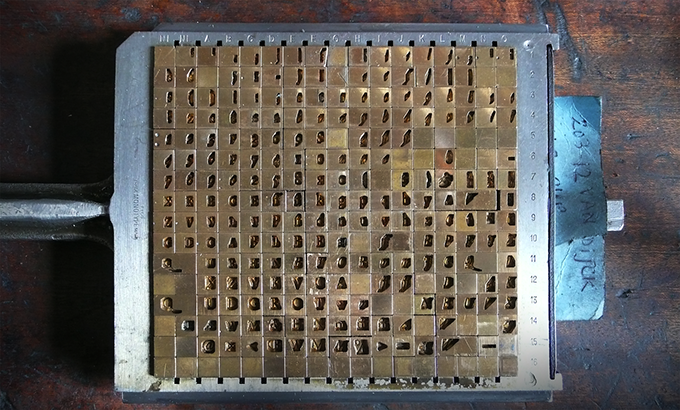

The matrix case, 255 individual Monotype matrices (seven alphabets, figures, punctuation, etc.).

The matrix case presented to the mould in the Monotype composition caster.

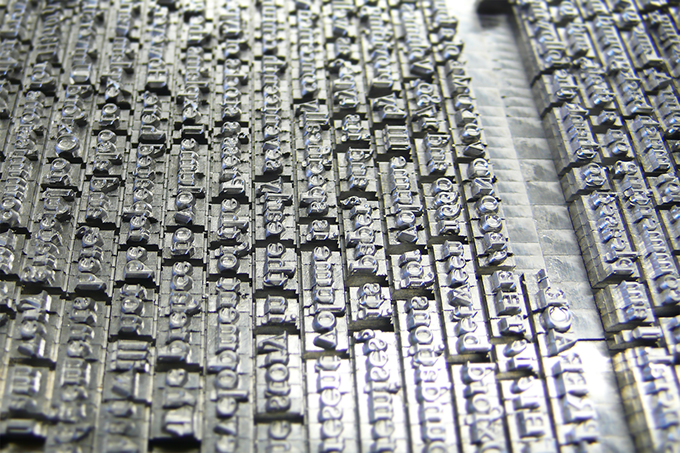

The Monotype composition caster producing Large Composition type (18pt Baskerville series 169), character by character and 'justified' to the measure.

The hot-metal type comes out line by line and is pushed out onto the galley, a tray on which it is carried to a stone and made ready for the press.

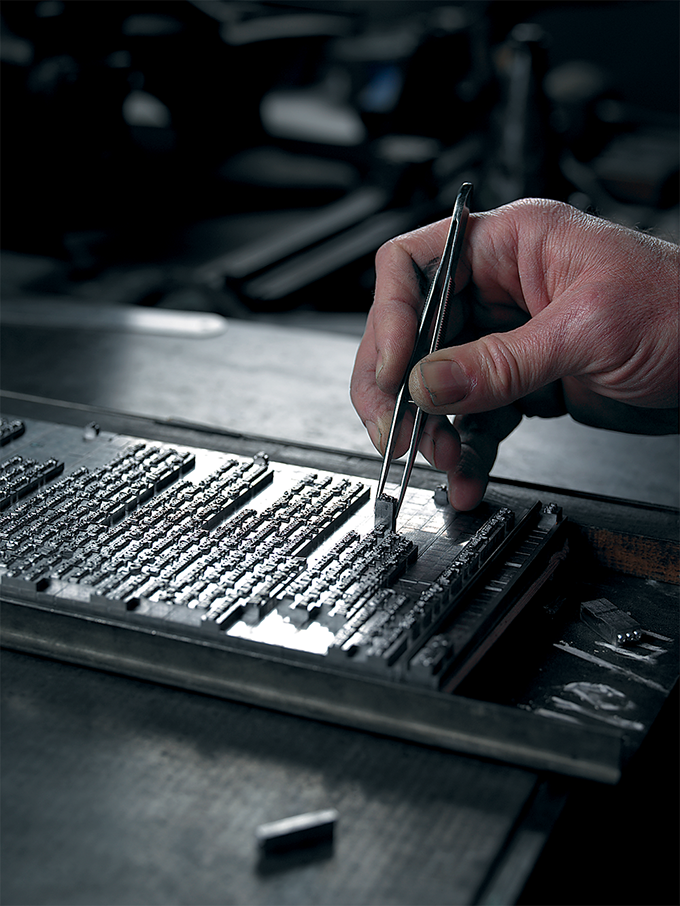

With all the elements of a page cast, I take them off the galleys onto a stone where they are arranged and locked up in a chase using blocks called furniture. A few adjustments are then made, called planing, to ensure they sit in perfect alignment.

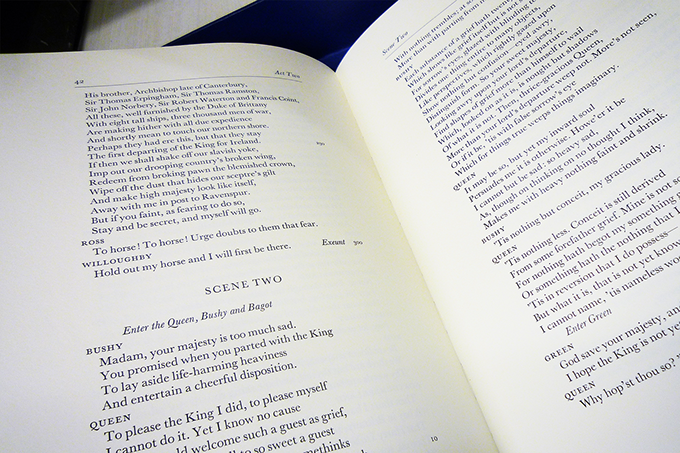

When the page has been put together and locked up securely, I can take it to the press for the first print. This initial test is the first time that the text is not in the form of hole-punched code or backwards letterforms, so a final scan for corrections is necessary before the pages are printed.

When a page is ready for the press, all the copies of that page are printed in one go. Printing is done page by page, and the books are then collated, ready to send to the binders.

To view samples of work I have typeset and printed, please see the Samples page.

07854 318 778

© Gloucester Typesetting 2016

Website by et al design consultants